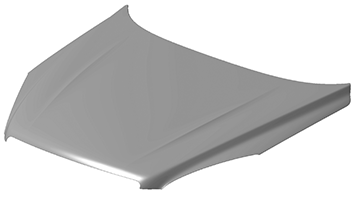

CJPROTEC’s technology turns imagination into reality.

We are recognized as the best prototype parts company with our R&D efforts and customer-oriented management.

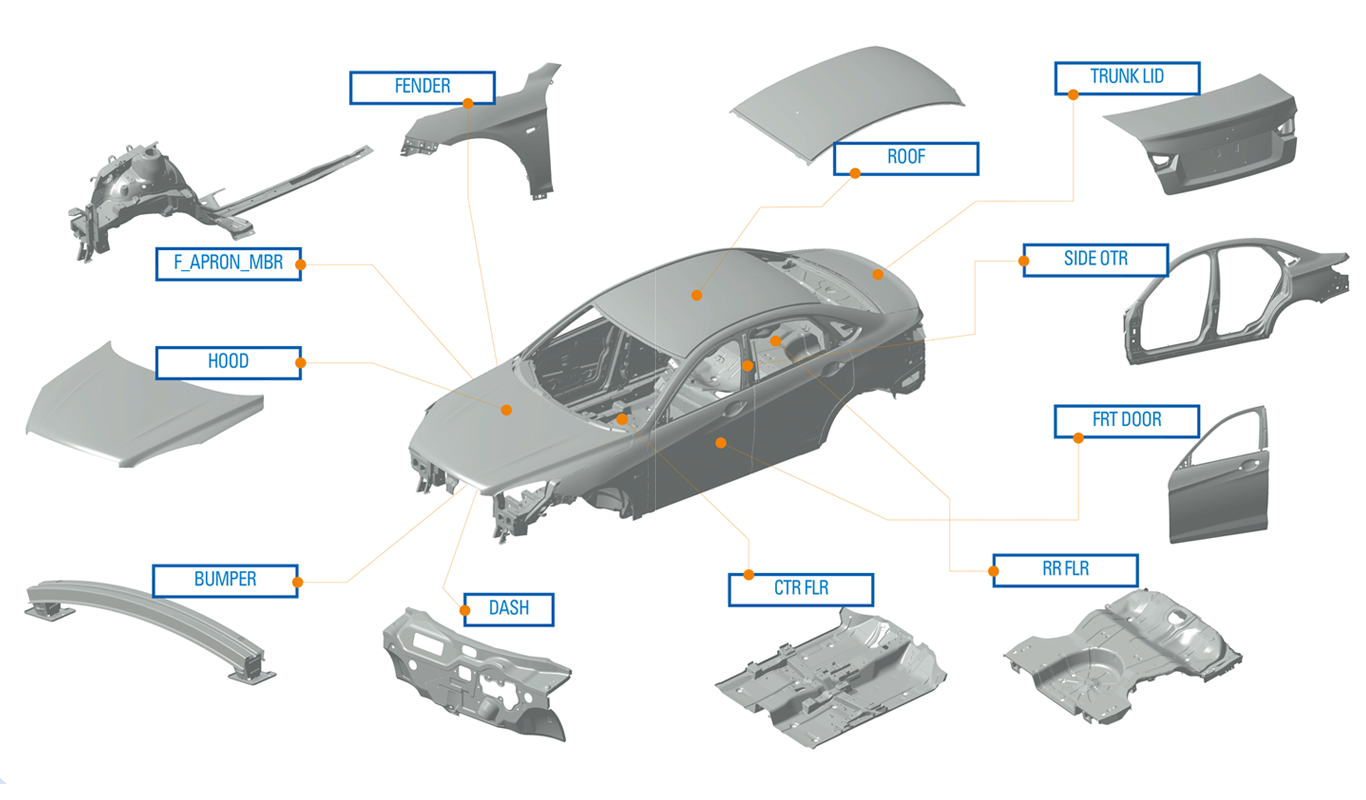

FRONT BUMPER BEAM

It plays a role to protect passengers by reducing impact in the event of a vehicle collision, and recently various sensors for driving assistance devices are installed.

Weight lightening and collision performance are improved by applying aluminum materials.

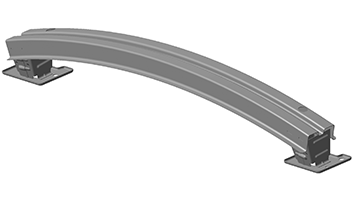

PNL ASSY-F/APRON & MBR COMPLETE

As the important frame constituting the front of the car body, it absorbs impact at a frontal collision, and absorbs and transmits load from road vibrations while driving. It is lightweight by applying aluminum material, and the mechanical fastening methods such as SPR are applied to assemble aluminum and steel parts.

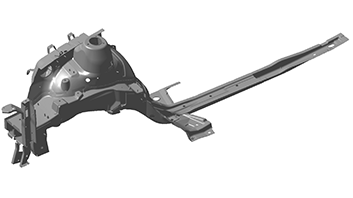

PNL & HINGE ASSY-HOOD

As a part that protects the engine room of a vehicle and determines the design of the front part, it acts as a shock absorbing structure to reduce injuries in the event of a frontal collision. Aluminum plates are used to reduce weight, and SPR and structural adhesive are used for bonding.

PNL ASSY-FRONT & REAR DOOR

Located on the side of a vehicle, it is used as the space for passengers to get on and off, to protect passengers from the external impact of the side, and plays a role in which various convenience parts are installed. Aluminum plate and aluminum extruded materials are applied to reduce weight, and SPR, high-strength aluminum spot and laser welding are used for bonding. The relevant technology has been successfully applied to the development of JK1 vehicle.

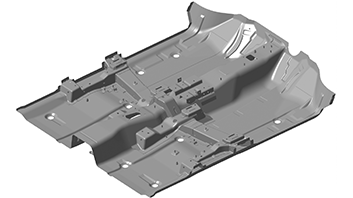

PNL ASSY-CTR FLOOR COMPLETE

It plays a role to connects the front and rear of the car body, and has the structure to protect the passenger space in the event of front and side collisions. It blocks external moisture, dust, heat and noise, and is equipped with a seat and drive exhaust braking system. For EV models, a battery case is installed. Lightweight materials and new molding methods are applied to secure the structural rigidity.

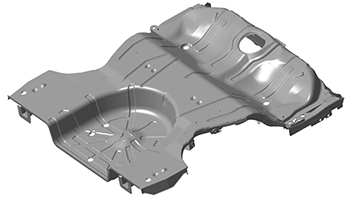

PNL & MBR ASSY-RR FLR COMPLETE

It is the main frame at the rear of a vehicle, and plays a role in ensuring the safety of passengers in the event of a rear-side and rear-side collision. Rear seats, fuel tanks, etc. are installed. For EV models, a battery case is installed. Lightweight materials and new molding methods are applied to secure the structural rigidity.

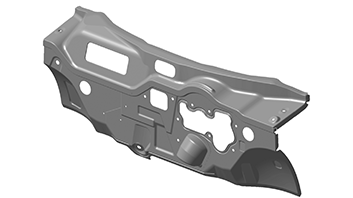

PNL ASSY-DASH COMPLETE

It is designed to separate the engine room and the passenger space, supporting the car body load in the front part. The function of soundproofing, dust-proofing, watertightness and heat insulation are required. COWL cross bar is installed to assemble interior materials for operator’s convenience. Hot stamping molding technology is applied to improve the performance of the frame structure.

PANNEL ASSY-TRUNK LID

It determines the design of the rear part of a vehicle, and serves as a cover to protect cargos in the trunk. Aluminum plates and aluminum extruded materials are applied for weight lightening, and SPR, high-strength aluminum spot and brazing welding are applied for assembly.

PANNEL SIDE OTR

As the main frame part that supports the front of a vehicle and the passenger space, it support the load of a vehicle in the event of a vehicle overturn. It has the structure that absorbs shocks in the event of front and side collisions, and provides the mounting point for door mounting. Ultra-high tensile steel forming technology is applied to improve the vehicle performance.